Load capacity of tie-wires

This module is determining the load capacity in compression and tension for tie-wires taking into consideration the differential movement and the pre-usage deformation.

The method is in the SBI – Guideline 157 (Danish) described and is a pure statically approach.

The principle in the method is below briefly described:

The load on tie-wires generally is axial forces and movements

The axial forces are compression or tension normally due to distribution of windload to the leaves

Differential movements between inner and outer leaves is caused by differences in moisture and especially temperatures. Short and stiff tie-wires are sensitive to differential movements

Tie-wires are not straight when placed in the joints causing a reduction of the load capacity.

Type of inner leaf

The program needs to know, which type of inner leaf is used, to decide which anchorage strength is relevant in the calculations as upper limit for the bearing capacity of the tie-wire.

The outer leaf is always assumed to be masonry. If storey high light weight concrete elements is chosen as material for the inner leaf, the program selects the lesser of the two anchorage strengths, stated in the relevant input fields. If masonry is chosen as material for the inner leaf , the program selects the anchorage strength stated in the relevant input field. If the inner and outer leaf are composed of two different types of masonry, the lesser of the two anchorage strengths should be given in the input field

Type of curvature and pre-usage deformation

In many situations, tie-wires are not 100 % rectilinear.

In this program it is possible to take into account different types of deviation from the rectilinear form. The curvature types are bended tie and curved tie.

A bended tie has an s-shaped curvature in one end, stretching over a length of about 10 mm, and is rectilinear in the rest of the length. A curved tie has an even, one-sided curvature stretching over the entire length.

The pre-usage deformation is the largest distance from a point on the tie to a straight line between the two end points. Pre-usage deformation appends to the deformation being present before the tie is subjected to further deformations caused by differential movements.

You can see an illustration of these conditions by pressing the button marked "Drawing", having defined a tie as either bended or curved, and entering a relatively large deformation and setting the differential movement to zero.

Ties imbedded in storey high prefabricated concrete or light weight concrete walls, are often bended align with the face of the wall, to ease transport, etc. It can be difficult to straighten these ties perfectly at the construction site, and the curvature type should be stated as "bended".

Diameter of tie-wire

A larger diameter of the tie-wire results in larger stress from the differential movements. Even if the tie-wire's bearing capacity is increased, it may be that the total "surplus" of bearing capacity for normal forces is decreased.

The anchorage strength of the tie-wire will increase, when the diameter of the tie-wire is increased.

Differential movements

The inner leaf of the wall is considered to be in a constant climate and not exposed to deformations caused by temperature or humidity. The temperature and moisture content of the outer leaf, however, changes over a 24 hour period, and over the year, causing it to move in relation to the inner leaf.

| Difference in temperature: | 35 °C (this value may vary from country to country) |

| Expansion coefficient: | 0.006 mm/(m * °C) |

| Total in-plane extension: | 0.21 mm/m |

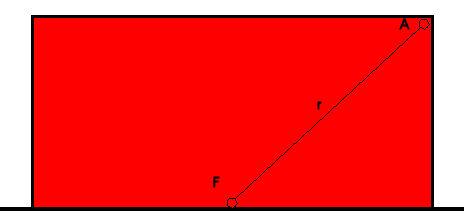

Figure 1. Differential movement

Characteristic modules of elasticity

The characteristic module of elasticity for the tie-wire. The most common material are stainless steel and tin bronze. For these materiales following values for the characteristic modules of elasticity can be assumed:

- stainless steel: 200.000 MPa

- tin bronze: 120.000 MPa

Large differential movements require flexibel tie-wires. 3 mm tie-wire of tin bronze 720 MPa is among the most flexible.

Characteristic anchorage strength in storey high light weight concrete elements

The characteristic anchorage strength can be determined by testing, or supplied by the manufactor of the element.

The value is transferred automatically from the heading "LW Concrete (EN 12602)". The value can, of course, be overwritten in the current calculation.

Characteristic anchorage strength of tie-wires in masonry

The tie-wire's characteristic strength can be determined by testing with the masonry in question. The values are usually given by the producers of the tie-wires.

The value is automatically transferred from the module "Masonry". The value can, of course, be overwritten in the current calculation.

If the inner and the outer leaf are of two different types of masonry, the lesser of the two anchorage strengths is used.

Characteristic yield strength

The characteristic value of the yield strength of the material composing the tie-wires. The most common materials are stainless steel and tin bronze. The following values can be used for these materials:

| Stainless steel: | 600 MPa |

| Tinbronze 720: | 720 MPa |

| Tinbronze 480: | 480 MPa |

With large differential movements, it may be necessary with a small diameter and a small ratio between module of easticity and yield strength. 3 mm tie-wires made of tinbronze 720 are the most flexible among the common materials.

Free length of tie-wires

The free length of the tie-wire is the distance between the inner sides of the leafs. The tie-wire is considered to be restrained in these points